Growing Crystals

After completing his classical training as a scientific glassblower in the Inorganic Chemistry Laboratory at Oxford University, Richard Morgan went on to set up the Lab in the Chemistry Department at the University of Hull in the U.K. One of their goals was to grow Crystals. That was some fifty years ago. Crystal growth has come a long ways since then, and research seems to be expanding all over the world. The potential of manufactured crystals is far reaching.

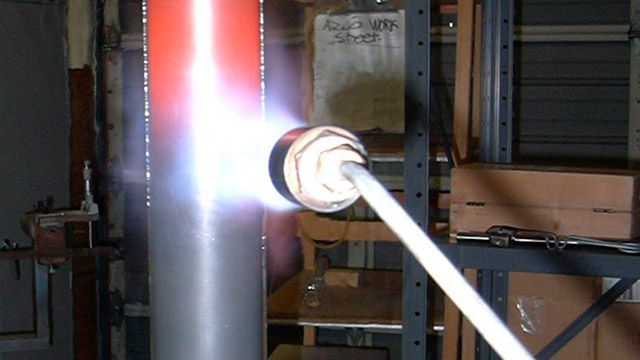

The Flux method is one example of how crystals can be grown. Sandfire Scientific has Developed a method to manufacture Crystal growth ampoules that are 6mm to 125mm ID X 800mm Long shrunk over the entire length. And we also make our own carbon former/mandrel to suit our clients’ needs.

A Quartz tube is shrunk on a carbon mandrel to form an ampoule. The ampoule may then be coated with a thin layer of high purity carbon. This type of ampoule is often used to grow semiconductor crystal ingots, and the carbon coating facilitates its removal, enabling the operator to reuse the same pyrolized ampoule. An example would be monocrystalline ingots for solar cell wafers. There are other instances where carbon cannot be used, so either a plain ampoule or precision tapered ampoule would be indicated. If a plain ampoule is used, then usually the plain ampoule is broken in order to remove the material. Please see our October 2012 news blog about carbon coating.

Sandfire Scientific has supplied crystal growth ampoules to a number of universities and research facilities in different parts of the world. If you wish to obtain an excellent ampoule, carbon coated, or not, please contact us. Our work is guaranteed.