Technology Innovation

Sandfire Scientific Ltd has been manufacturing custom-made scientific glassware for over 40 years. And even after all this time, the requests we receive from our customers never cease to amaze us.

Sandfire Scientific Ltd has been manufacturing custom-made scientific glassware for over 40 years. And even after all this time, the requests we receive from our customers never cease to amaze us.

Hydrophobicity. Now, there’s a word you don’t hear every day. It is the property of a hydrophobe molecule, which, as its name implies is horrified by water. Well, in reality, it is not so much repulsed by water as it is not attracted to water.

Chemists and researchers want to prevent certain compounds, such as fats, oils; greasy substances, and other solutes in general, from adhering to surface of their beakers, etc.

That’s where silanization comes in. Silanizing, or siliconizing as it is often called, prevents the absorption of solutes to glass surface; thereby increasing the hydrophobicity. By silanizing or siliconizing, a bond is formed with the glass, thanks to triethoxysilane.

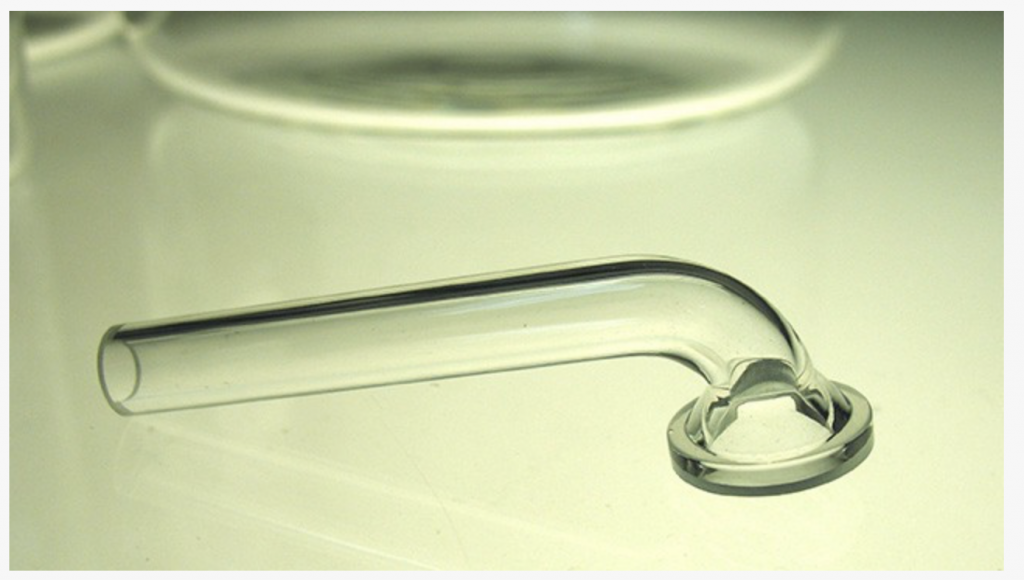

We recently shipped silanized beakers to one of our customers. We also shipped to another customer some inlet liners that are used in scanners in many airports around the world. Silanization is particularly important when dealing with low concentrations of particularly “sticky” solutes such as single-stranded nucleic acids or proteins or cells. In order for the liners to function correctly, they have to be silanized. This process ensures that trace amounts of material to be tested pass through the liner to the testing surface, rather than being absorbed onto the surface of the glass liner. Non-silanized liners will not read accurately or consistently. The photos show the beakers and inlet liners that we have silanized.

Silanization is one of the many services we offer at Sandfire Scientific. Contact us today for all your silanizing (siliconizing) needs.